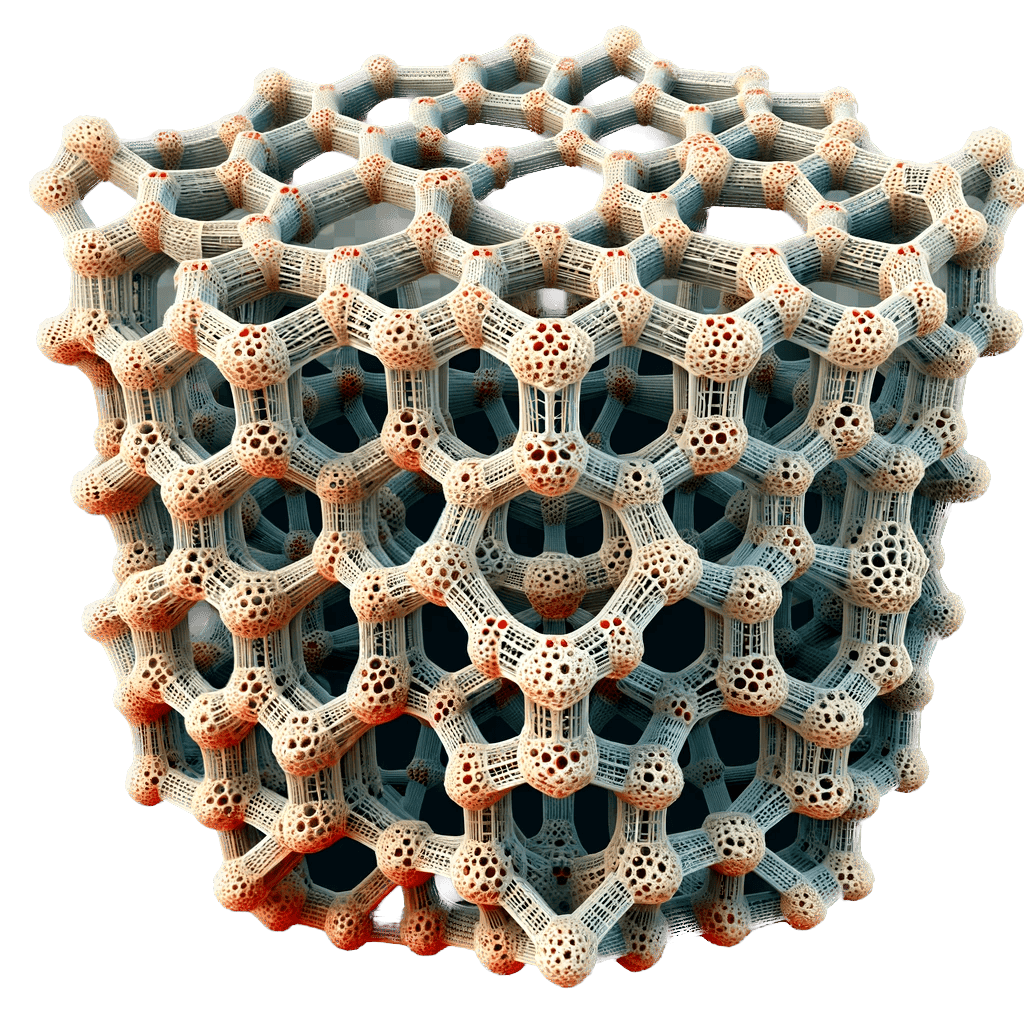

Variable Cell Zeolite Technology (Vari-Zeo™)

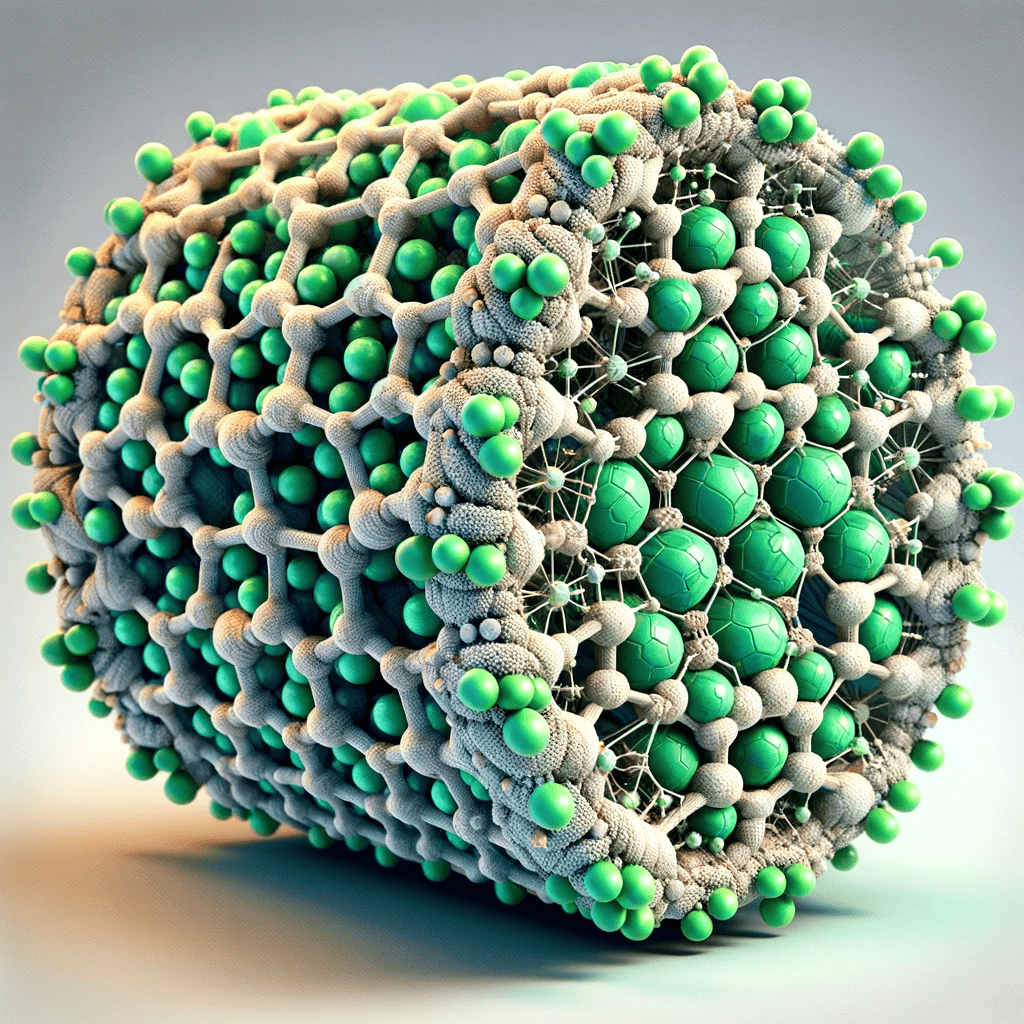

A tecto-silicate lattice structure with a cell shape and size distribution range that is engineered specifically for the contaminant species to be removed. 98% of the surface area is internal, allowing Total Encapsulation of contaminant species with varying molecular weights for greater retention capacity and accelerated removal rates.

CLS engineered variable cell size zeolites are the foundation of every product we make and supply.

Figure 1: Vari-Zeo™ Fresh

Figure 2: Vari-Zeo™ Saturated

0%

market share in the US CI Removal Industry by total volume.

0+

absorbent systems supplied

0%

of all raw materials used are sourced within the United States.

0

Years in Business

0%

Customer Retention

Industrial Applications That Power Long-Term Success

CLS Industrial Purification has designed and installed HCl, RCl, H2S, R-SH and Hg removal systems in over 600 reactor cycles worldwide based on our proprietary Variable Cell Zeolite technology, manufactured in Texas.

Our engineered manufacturing process combined with a systematic method of modeling, monitoring, and testing provides a result that is a measurable value for our clients in the form of decreased corrosion, lower maintenance costs, and better more reliable downstream operation.

Certified Purification from Offshore to Downstream

CLS provides certified purification in fixed bed absorbent applications across the entire energy vertical and is a trusted leader for the removal of key contaminants:

Absorption of organic and inorganic chlorides for Total Cl removal in gas or liquid phase Reformer (CCR) applications. No side reactions or green oils are made in the process.

Leading the oil and energy industry in the removal of element and organic mercury from raw natural gas and condensate upstream applications.

Absorption of mercaptanic, thiophenic, and benziothiophenic species for Total S removal in addition to absorption of organic and inorganic arsine. CLS S and Arsine guard beds purify gas or liquid phase streams in natural gas, refining, and petrochemical applications.

Absorption of H2S and mercaptans from raw and condensate natural gas sweetening, refinery gas and liquids, and bio gas sweetening.

Advantages of Manufactured Absorbents from CLS:

Specializing in total chloride, mercury, sulfur, and arsine removal, CLS Industrial Purification offers key advantages over competitors.

Every application is unique and engineered specifically to each client.

Fluid Dynamics and Bed Design

Optimizing Flow for Maximum Efficiency

CLS’s Vari-Zeo™ technology leverages advanced zeolite design and vessel sizing for enhanced fluid dynamics, ensuring optimal purification and addressing system vulnerabilities in existing setups.

Loading and Operational Efficiency

Streamlined Sock Loading Process

The Vari-Zeo™ beds feature a streamlined sock loading system from super sacks for uniform distribution and optimal operation, enabling rapid loading rates and consistent, efficient performance.

Performance Monitoring and In-Situ Testing

Precise Data for Continuous Optimization

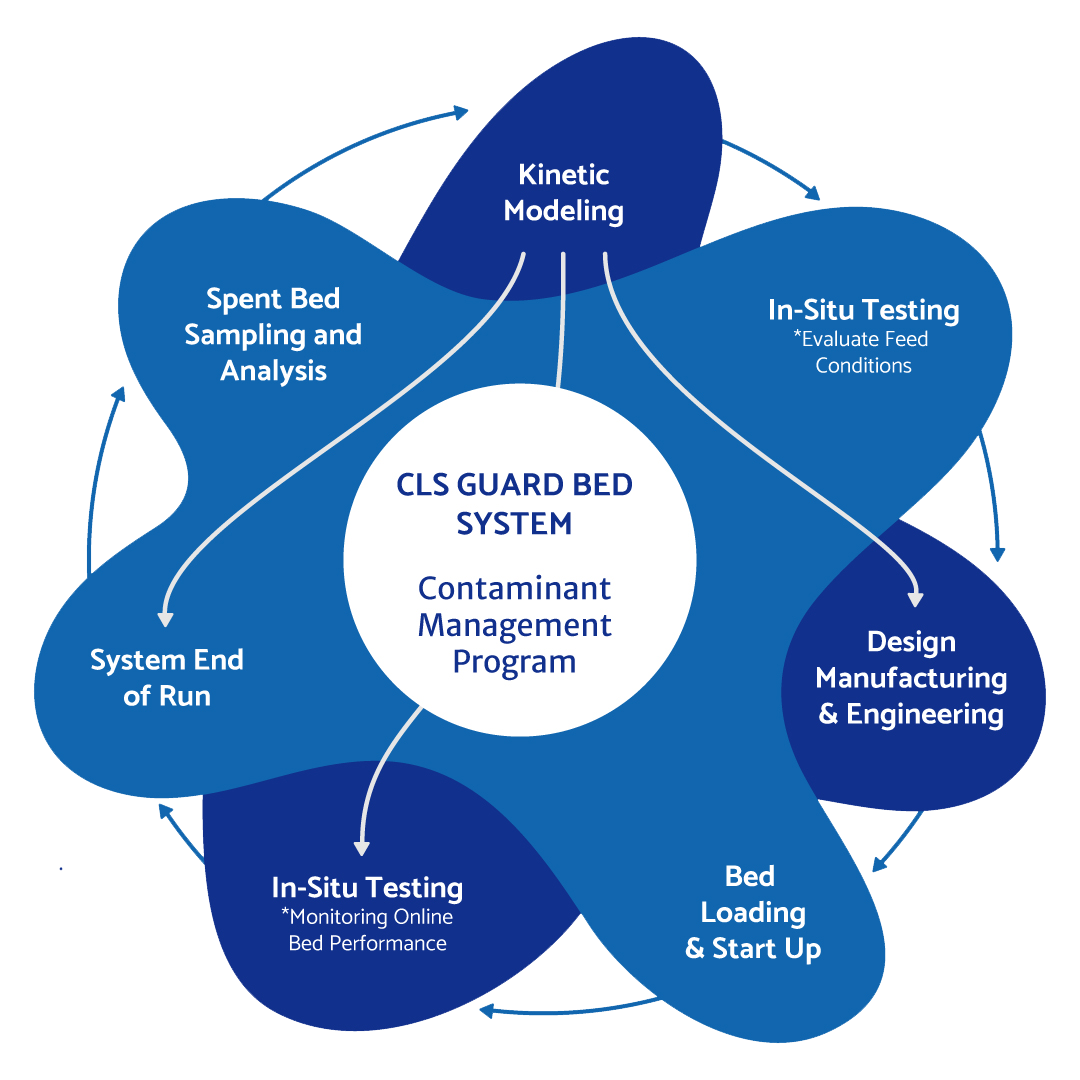

CLS’s purification systems undergo thorough in-situ and lab testing, ensuring continuous performance optimization through accurate data analysis and kinetic modeling to meet dynamic client needs.

Discharging Spent Bed and Maintenance Operations

Maintenance Efficiency through Advanced Material Design

Vari-Zeo™’s water-resistant design allows for safe and simple maintenance procedures like steam purging or water washing, eliminating complex steps and reducing downtime in bed replacements.

Spent Sample Testing and Analysis

Detailed Post-Operative Insights

After each cycle, CLS analyzes spent samples to assess contaminant uptake and bed performance, providing insights for system improvements and customer awareness of saturation and speciation.

Contaminant Management Program (CMP)

Ensuring Continuous System Excellence

CLS’s CMP focuses on relentless monitoring and optimization, guaranteeing sustained peak efficiency and performance reliability throughout the system’s lifecycle.

Customization and Reliability

Tailored Solutions for Unmatched Performance

CLS’s Vari-Zeo™ technology offers bespoke solutions through precise kinetic modeling and continuous performance monitoring, ensuring optimal bed utilization and alignment with operating conditions.

Industry Expertise and Comprehensive Service

Over Two Decades of Specialized Purification

With more than 950 charges supplied, CLS’s expertise in industrial purification is unmatched. Our solutions are comprehensive, from bed loading to spent material discharge, offering several key advantages:

- Performance unaffected by moisture in gas streams.

- Elimination of hot nitrogen requirements through steam-out purging.

- Accelerated purging times for operational efficiency.

- Rapid change-out with free-flowing spent material.

- Safe encapsulation of contaminants within the zeolite structure.

- Disposal as Class 2 Non-Hazardous waste, simplifying environmental compliance.

- High activity and small mass transfer zones leading to superior bed utilization.

Get In Touch With The Industry Experts

Interested in learning how CLS Industrial Purification’s technology can benefit your industry application(s)? Contact our team.